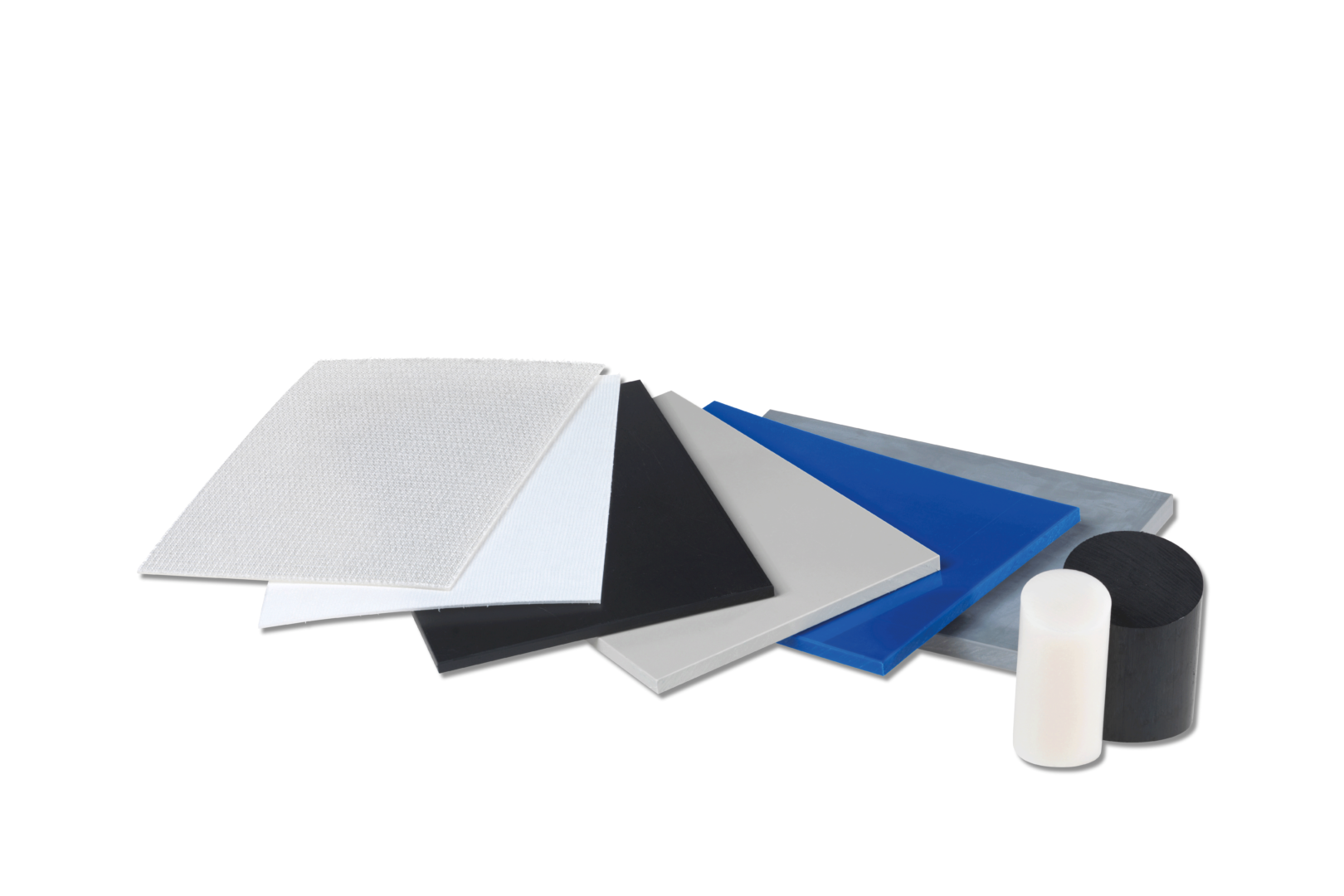

Semi-finished products

AGRU semi-finished products made of thermoplastics are an excellent and durable solution for

modern, premium apparatus and tank construction, and for manufacturing wear-resistant products.

In the chemical and heavy industries, and in plant construction.

Product range

Made of PE, PP, PVDF, ECTFE, FEP and PFA plastic materials:

• Sheets

• Fabric backed sheets

• Pipes

• Bars

• Welding rods

• Tanks

• Custom tailored solutions

We are the representative of the Austrian company Agru Kunststofftechnik GmbH.

The following plastic materials are used for the production of semi-finished products:

• Standard materials – PE and PP

• High-performance materials – PVDF and ECTFE

• Ultra-high-performance materials – PFA and FEP

• Polyethylene – PE100 and PE100-RC semi-finished products:

– a high level of mechanical strength

– very good chemical resistance

– temperature resistance –40 °C and +60 °C

– good resistance to wear

– very good electrical insulation

– high vibration damping

– good light and weather resistance

– good material also for the production of taylor-made tanks

– HDPE-el ESD plastic material – due to their special electrical properties, these semi-finished products are particularly well suited to

transporting highly flammable media or dusts

• Polypropylene – PP semi-finished products:

– similar to PE, but with higher stiffness, strength, and hardness levels

– very good chemical resistance

– temperature resistance –5 °C and +90 °C

– ideal material for the use in pickling plants, the chemical industry, and also for extremely aggressive waste water, as chemicals are used at high

temperatures in these areas

– PPs – with low-flammability

– PPs-el ESD – Low-flammability and electrically conductive and electrostatic charging is prevented

• Fluoropolymers – PVDF, ECTFE, FEP and PFA semi-finished products:

– depending on the application temperature, media and concentration

– can be used as structural materials or as corrosion protection lining

– extremely high corrosion resistance

– very good chemical resistance

– temperature resistance –190 °C and +260 °C

– exceptional weathering and UV-resistance

– semi-finished products made from PVDF ja PFA plastic materials are therefore ideal for applications with ultrapure water and highly purified

chemicals and for cleanroom use

– as a result of their surface tension, fluids have the tendency to minimise their surface area and try to revert to a spherical shape. They

therefore pearl off the hydrophobic surface of fluoropolymers, taking dirt particles with them

• PVDF plastic material:

– it possesses good radiation resistance, which makes it ideal for high-end applications in the semiconductor, pharmaceutical, life science and

photovoltaic industry

– thanks to the excellent leaching behaviour it is good material where required high media purity and leaching behaviour standards

– PVDF-el ESD (electrically conductive or electrostatic discharge) can be equipped with electrically conductive particles especially for the

electrical industry and explosion-proof areas

– PVDF Flex material has excellent flexibility

• ECTFE plastic material:

– excellent resistance to the corrosive influence of heat, strong radiation, and weathering

– high impact resistance

– shows almost no property changes in a wide temperature range

– compared to PVDF, ECTFE has a better chemical resistance, especially when exposed to lyes

• FEP plastic material:

– outstanding corrosion resistance

– temperature resistance –190 °C and +205 °C

– good flexibility and thermoformability

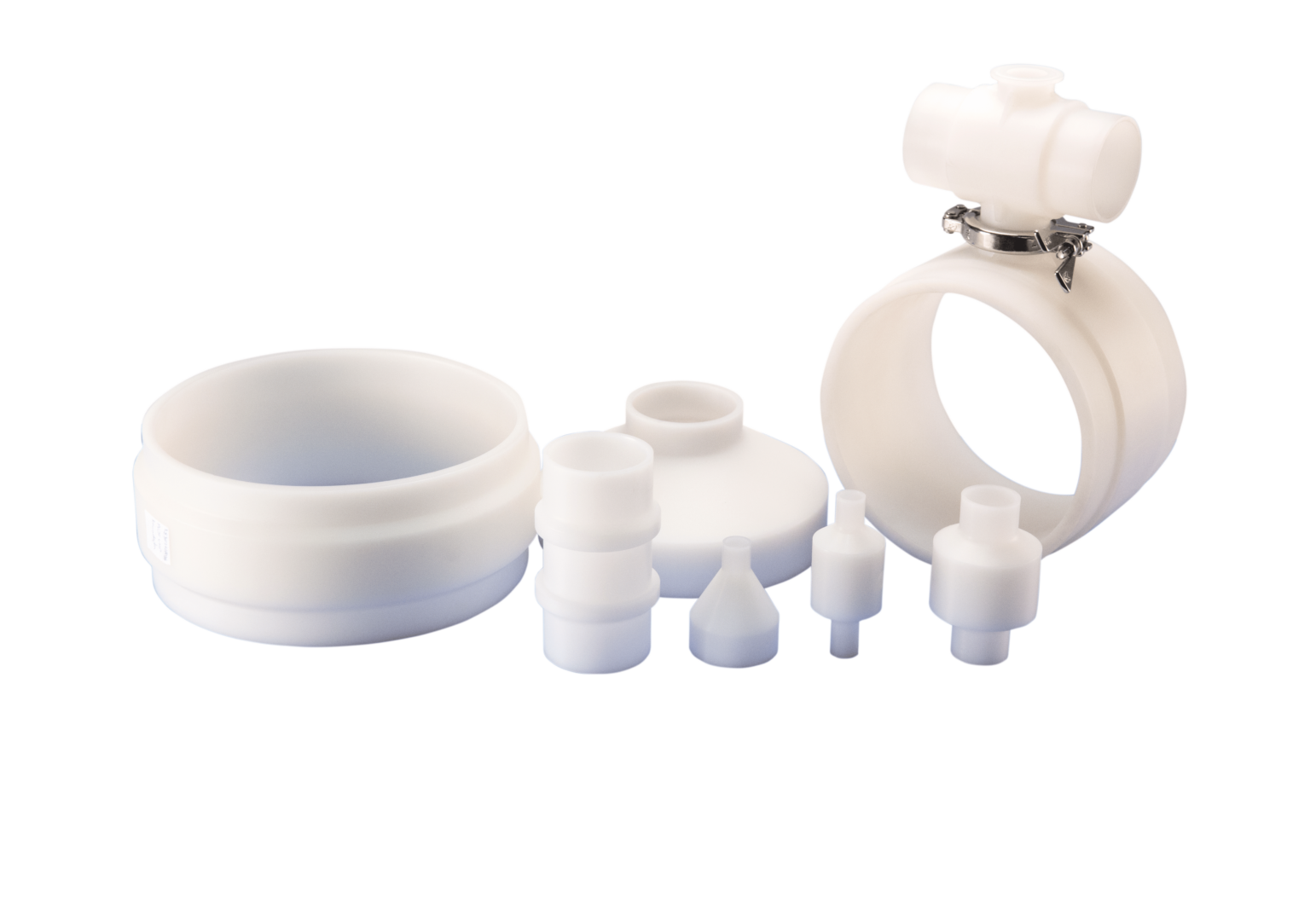

• PFA plastic material:

– the highest grade plastic in the AGRU portfolio

– suitable for an extremely broad spectrum of applications

– temperature resistance –190 °C and +260 °C

– the products made of PFA are also available in HP (High Purity) quality. The HP quality means it can be used for applications in the semiconductor,

pharmaceutical, and food industries that require high purity levels

• Tanks made of fibre-reinforced plastic (FRP):

– to maintain chemical resistance and leak-tightness of tanks, boilers, reactors and scrubbers

– lined with fabric backed sheets

– suitable for operation under vacuum and pressure up to 180 °C (depending on material and chemical)

• Fabric backing systems for plastic sheets:

Plastic sheets (PE, PP, PVDF, ECTFE, FEP ja PFA) with different fabric packing systems:

– Polyester fabric – most economical and proven solution

– GGS Glass fabric – extreme temperature stability, good thermoformability and good bonding strength

– SK+ Optimised synthetic fabric – very high hydrolysis resistance, top resistance against acids, high bond strength at high operating temperatures

• Fabric packed pipes:

– HV-Liner pipes

– SK+ ja GGS laminated pipes